Artificial Intelligence (AI) has emerged as a pivotal force driving transformation and addressing complex challenges in the rapidly evolving supply chain and logistics landscape.

Integrating AI technologies is not just enhancing operational efficiencies; it's reshaping the entire industry paradigm.

From generative AI revolutionizing supply chain operations to advanced demand forecasting models, AI enables businesses to innovate beyond traditional constraints and meet the increasing demands of a globalized market.

- Generative AI is at the forefront, automating routine tasks and empowering professionals to focus on strategic, forward-looking decision-making. This shift is crucial for businesses aiming to operate on a predictive and proactive basis.

- Demand Forecasting leverages AI's capability to process and analyze vast datasets, offering unparalleled accuracy in predicting market demands and managing inventory effectively.

- Routing and Delivery Optimization sees AI minimizing lead times and transportation costs through advanced logistics planning.

- Loading Process Enhancement and Operational Procurement benefit from AI's efficiency improvements, making these processes more cost-effective and streamlined.

- In Supply Chain Planning and Warehouse Management, AI aids in forecasting and stock management, optimizing operations, and reducing waste.

- Supplier Selection is revolutionized with AI providing real-time data for making informed decisions.

AI's need to navigate the industry's modern challenges—such as increasing complexity, demand forecasting accuracy, operational efficiency, and real-time decision-making—is more apparent than ever.

AI's role in fostering operational resilience, proactive strategies, and market adaptability underscores its importance as a strategic necessity rather than a mere technological luxury.

As we delve deeper into the transformative impact of AI across the supply chain and logistics sector, we will explore how businesses can harness these technologies to stay competitive, reduce errors, and make informed decisions swiftly.

With Rapidops’ expertise in AI development, companies are positioned to fully leverage AI's potential, transitioning from traditional methods to innovative, data-driven strategies that promise a future of efficiency, growth, and sustainability.

Check our infographic to know how AI is revolutionizing the supply chain industry!

Download Now

Use cases of AI in supply chain and logistics

Integrating Artificial Intelligence (AI) into supply chain and logistics operations heralds a new era of efficiency, accuracy, and innovation.

AI sets new operational excellence standards by automating complex processes and enhancing decision-making. This section delves into the pivotal use cases of AI across both domains, illustrating its transformative impact.

AI use cases in supply chain

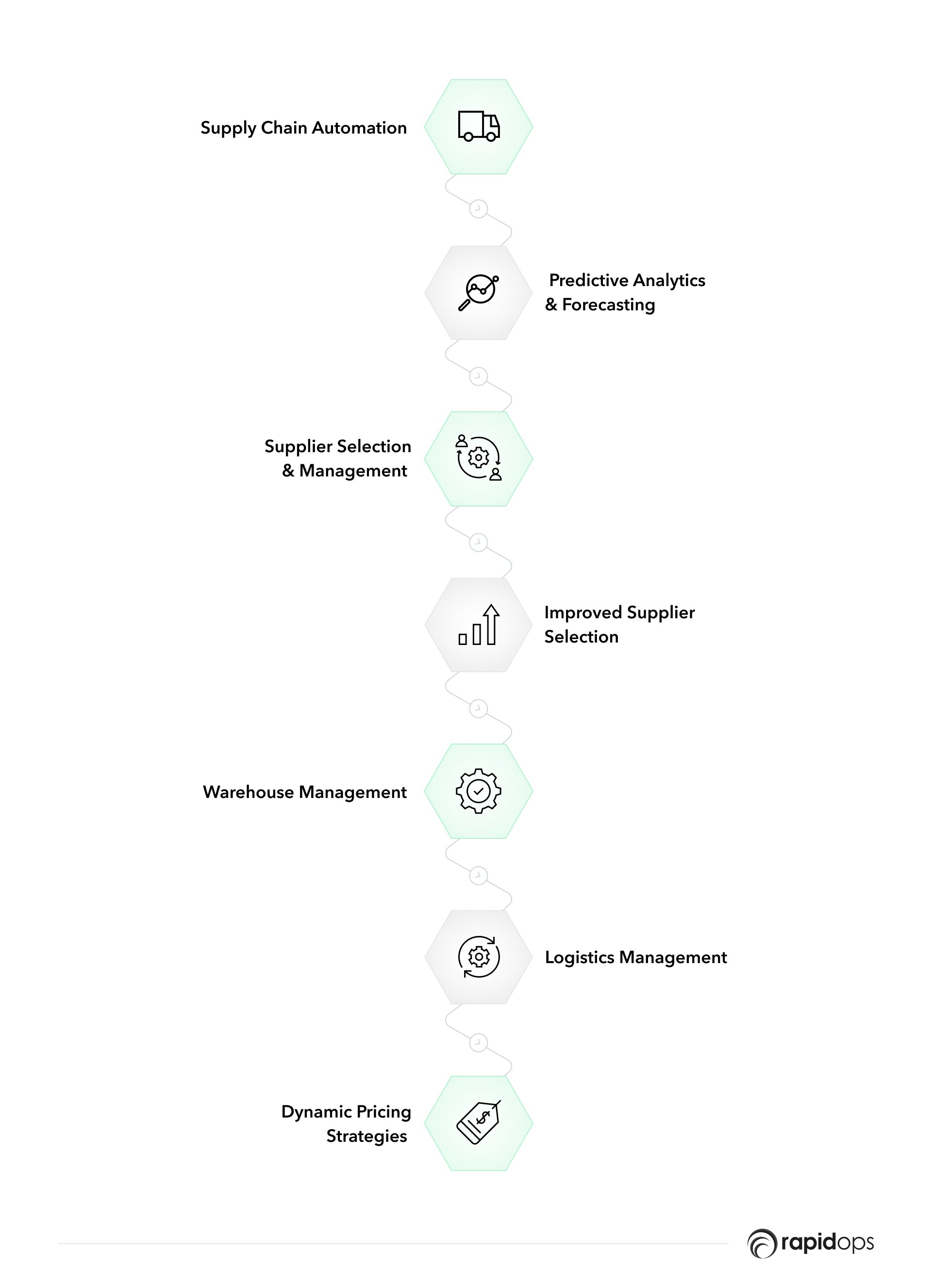

1. Supply chain automation

The cornerstone of modern supply chain automation, AI technologies such as digital workers, warehouse robots, autonomous vehicles, and Robotic Process Automation (RPA) are redefining efficiency. They take on repetitive, error-prone tasks, allowing for seamless, automated operations that significantly reduce the margin for error.

2. Predictive analytics and forecasting

AI's ability to analyze vast datasets enables unprecedented accuracy in demand forecasting. This analytical prowess extends to capacity forecasting and labor spending optimization, offering a comprehensive view of future needs and enhancing the strategic planning process.

3. Supplier selection and management

Through AI and Machine Learning (ML), businesses can track performance metrics, develop benchmarks, and make informed decisions on supplier selection, ensuring partnerships are both strategic and beneficial.

4. Inventory and production planning

AI-driven systems excel in striking the perfect balance between stock levels and lead times, addressing the critical challenges of understocking and overstocking. Digital resource mapping ensures resources are optimized, meeting delivery deadlines consistently.

5. Warehouse management

In the controlled environment of a warehouse, AI leverages activity-level data to simulate operations, optimizing product placement, layout, and labor allocation to enhance overall performance.

6. Logistics management

AI plays a critical role in overcoming logistics challenges such as traffic congestion. AI ensures timely deliveries through optimized route selection and scheduling, minimizing potential fines from delayed shipments.

7. Dynamic pricing strategies

With AI, businesses can implement time-based pricing that adjusts according to market demands and competitor actions, maintaining competitiveness and maximizing profitability.

AI use cases in logistics

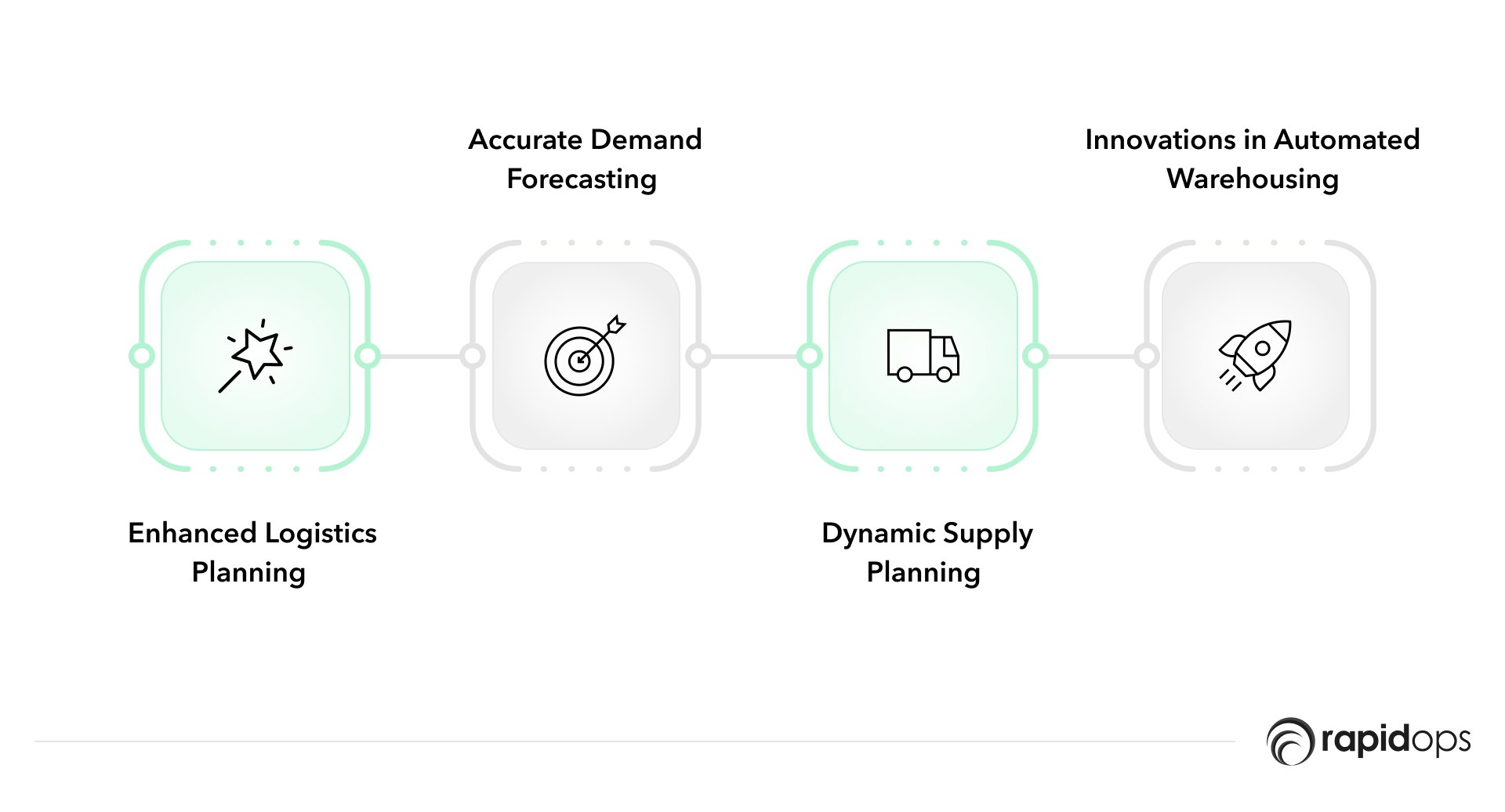

1. Enhanced logistics planning

Machine learning solutions provide a backbone for logistics planning, adept at handling scenario analysis and numerical analytics crucial for efficient coordination across the supply chain.

2. Accurate demand forecasting

Utilizing real-time data, AI-powered forecasting methods significantly reduce error rates compared to traditional approaches. This accuracy allows optimal vehicle dispatch, workforce planning, and reduced operational costs.

3. Dynamic supply planning

AI's real-time demand analysis enables dynamic updating of supply planning parameters, streamlining the supply chain flow and minimizing resource waste.

4. Innovations in automated warehousing

Projected to reach over 60% adoption by 2026, AI-powered warehouse solutions, including robotics, enhance supply chain management. The growth of the warehouse robotics market underscores the investment and confidence in AI's role in automating warehousing operations.

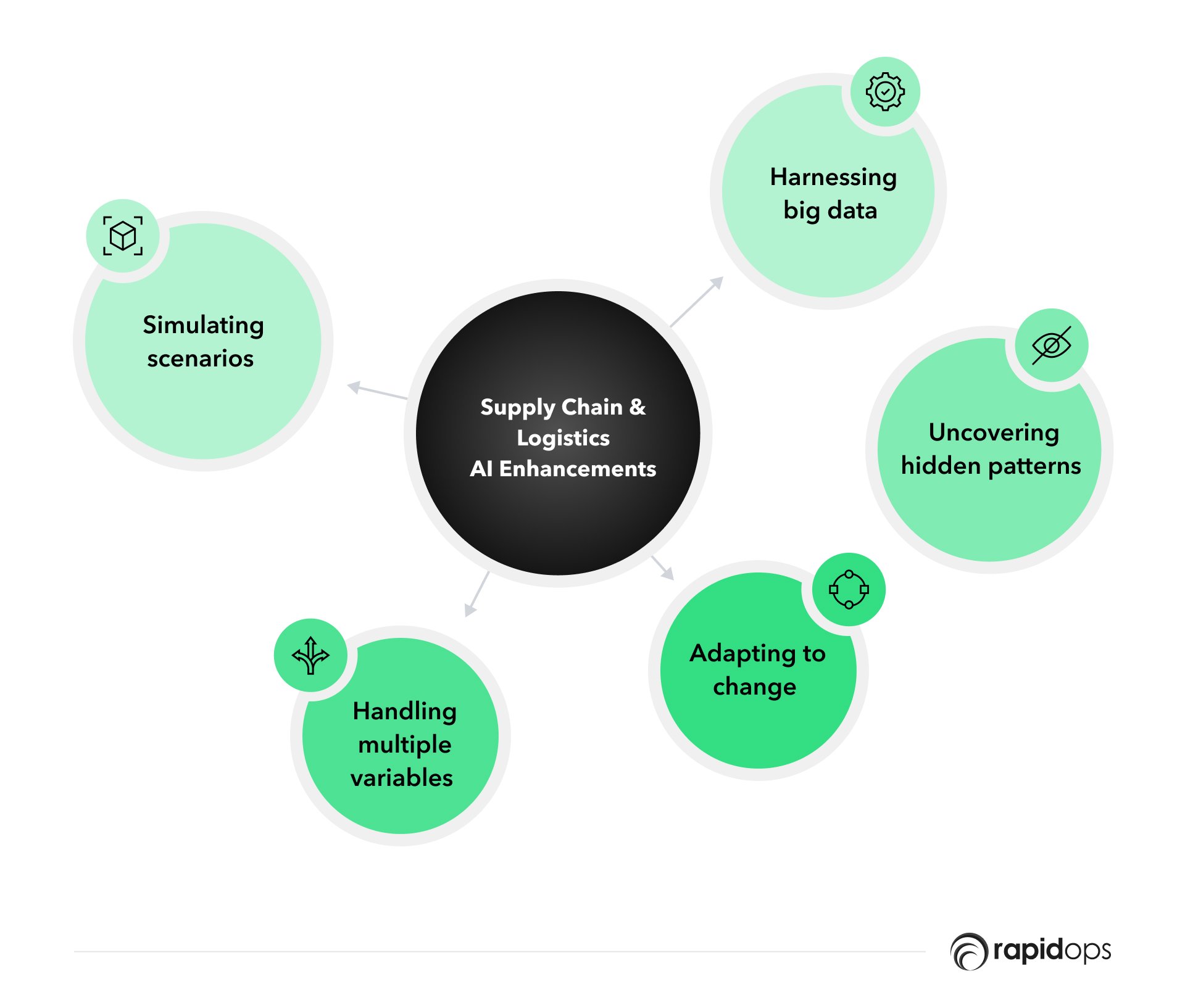

Enhancing forecasting and demand planning with AI

The leap from traditional forecasting methods to AI-driven approaches marks a significant evolution in how businesses predict future demand.

This transition is powered by AI models and predictive analytics' ability to harness big data, uncover hidden patterns, adapt to changes, handle multiple variables, and simulate scenarios.

Here's a closer look at these capabilities:

1. Harnessing big data

AI's capacity to digest and analyze data from diverse sources, including historical sales, social media, and economic indicators, equips businesses with a comprehensive understanding of demand drivers.

2. Uncovering hidden patterns

By employing sophisticated algorithms, AI identifies complex data patterns that elude traditional analysis, offering deeper insights into demand trends.

3. Adapting to change

AI models continuously learn from new data, enabling them to adjust forecasts in real-time to reflect market shifts and consumer behavior changes, proving invaluable during unpredictable events like the pandemic.

4. Handling multiple variables

Unlike traditional models, AI can evaluate the impact of numerous interrelated factors on demand, ensuring forecasts account for various influences.

5. Simulating scenarios

This feature allows companies to explore the potential effects of various strategies on demand, aiding in planning promotions, product launches, or adjustments for market fluctuations.

AI-powered demand forecasting is a game-changer, but remember, garbage in, garbage out. Human expertise in interpreting results and continuous model calibration are essential for maintaining forecast accuracy.

Combining AI's analytical power with human expertise ensures that businesses can make well-informed decisions, optimizing inventory levels, pricing strategies, and overall resource allocation for maximum efficiency and customer satisfaction.

Detailed case studies on AI in supply chain optimization

Let's gain some insight into supply chain AI optimization with the help of these case studies.

1. Consumer packaged goods (CPG) companies: Autonomous supply chain planning

McKinsey's research into the Consumer Packaged Goods (CPG) sector underscores the pivotal role of AI in enhancing supply chain performance. Traditional approaches often involve disparate point solutions focusing on individual processes without intercommunication or data integration.

This siloed strategy limits the potential benefits of AI in supply chain optimization. However, pioneering CPG companies embracing autonomous supply chain planning have witnessed significant gains:

Revenue increase

Leveraging AI for supply chain planning has led to revenue boosts of up to 4% by enabling more responsive and customer-oriented product distributions.

Inventory reduction

AI's predictive capabilities help reduce inventory by up to 20%, minimizing holding costs and reducing waste.

Supply chain cost decrease

Streamlined operations facilitated by AI contribute to supply chain cost reductions of up to 10%, enhancing overall profitability.

2. Amazon: Global Demand Forecasting with Machine Learning

Amazon exemplifies the power of AI in global demand forecasting. By employing machine learning algorithms, Amazon can predict future demand for millions of products worldwide in mere seconds. This predictive prowess allows for the following:

Effective inventory management

Amazon achieves optimal inventory levels, ensuring product availability while avoiding overstocking.

Operational efficiency

The ability to anticipate demand enhances Amazon's supply chain agility, enabling quicker response to market changes.

3. Ocado: Warehouse automation through AI-enabled technologies

Ocado stands at the forefront of warehouse automation, utilizing AI-enabled technologies to revolutionize inventory management. The deployment of collaborative robots (cobots) and other AI-driven tools achieves:

Enhanced efficiency and productivity

Cobots work alongside human operators, speeding up the picking and packing processes and reducing the time from warehouse to customer.

Improved safety

Automated systems minimize the need for human workers to perform hazardous tasks, enhancing workplace safety.

4. BMW: Quality assurance with AI-powered computer vision

BMW's adoption of AI-powered computer vision systems showcases AI's application in manufacturing quality assurance. These systems scan car models on the assembly line to identify defects, resulting in:

Improved product quality

Real-time detection of anomalies ensures that only cars meeting BMW's high-quality standards reach customers.

Operational efficiency

Automating quality checks accelerates the inspection process, reducing bottlenecks in production.

These case studies vividly illustrate AI's transformative impact on supply chain and logistics operations, from predictive demand forecasting and inventory management to quality assurance and operational efficiency.

By harnessing AI-powered tools, companies across various sectors are achieving unprecedented levels of supply chain optimization, setting new benchmarks for industry practices.

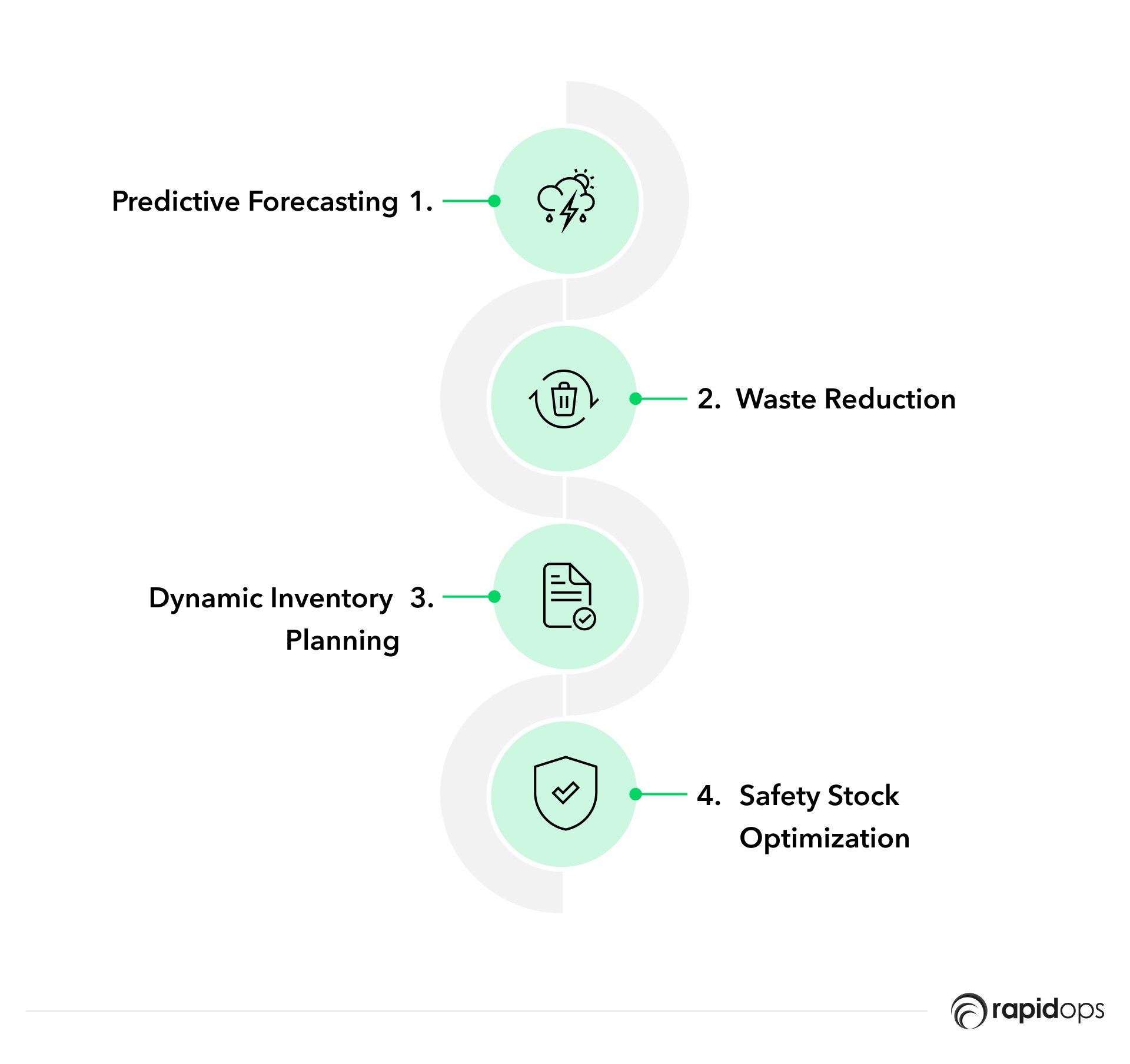

Optimizing inventory management through AI

Artificial Intelligence (AI) is the cornerstone of efficiency in the modern supply chain, ensuring businesses maintain the perfect balance between too much and too little inventory.

AI's role in inventory management is critical for adapting to the fast-paced market demands and reducing unnecessary waste. Let's explore how AI accomplishes this:

Predictive forecasting

Leveraging AI for predictive forecasting means businesses can use historical data, seasonality, and market trends to forecast demand accurately. This foresight allows for maintaining optimal stock levels and effectively adapting inventory to match customer preferences and market shifts.

Waste reduction

AI significantly reduces waste by addressing issues like overproduction and poor quality—one of the most preventable sources of waste in manufacturing. AI pinpoints quality issues through advanced analytics and machine learning, helping businesses solve them efficiently and reducing waste.

Dynamic inventory planning

Tools like Peak AI's dynamic inventory planning software analyze your inventory, sales, and other critical data to refine demand forecast accuracy. This ensures you hold the ideal inventory level across your network, avoiding excess stock and stockouts.

Safety stock optimization

AI optimizes safety stock levels, balancing maximizing margins and minimizing risks of stockouts or overstocking.

Such optimization is crucial for efficient distribution center management, ensuring you invest only in necessary stock levels.

By integrating AI into inventory management, businesses can achieve a dynamic balance that aligns with market demands, reduces waste, and streamlines operations.

This transformation makes supply chains more efficient, sustainable, and cost-effective.

AI in Logistics: Improving efficiency and reducing costs

Artificial Intelligence (AI) significantly impacts the logistics sector by enhancing operational efficiency, cutting down costs, and redefining the future of transportation and logistics operations.

1. AI in transportation

AI's integration into transportation is pivotal for achieving route optimization and reducing fuel consumption, leading to more sustainable and cost-efficient logistics operations:

Route optimization

Utilizing AI algorithms to process comprehensive datasets—including delivery addresses, times, traffic patterns, and weather conditions—facilitates the creation of the most efficient delivery routes. This optimization process not only shortens lead times but also minimizes transportation costs.

Fuel consumption reduction

The efficiency gained from AI-driven route optimization directly translates to a significant reduction in fuel consumption. This reduction is a win-win, lowering operational costs and lessening the environmental footprint of transportation activities.

2. AI in warehouse operations

The transformative power of AI extends to warehouse operations, streamlining processes and significantly reducing overhead costs:

Inventory management

AI enhances inventory control by analyzing market conditions, ensuring warehouses optimize stock levels. This optimization saves considerable cost by improving efficiencies and minimizing warehouse overhead expenses.

Warehouse robots

The transformative power of Artificial Intelligence (AI) in warehouse operations is not just a futuristic vision—it's a current reality that's reshaping how businesses approach supply chain management.

This transformation is evident in the warehouse robotics market's rapid growth, valued at $4.86 billion in 2022. With projections indicating an increase to $5.26 billion in 2023 and a significant jump to $12.99 billion by 2030, the trajectory for AI-powered robotics in logistics is not just upward but exponential.

This growth isn't just numbers; it represents a paradigm shift in operational efficiency, cost management, and scalability.

Dynamic planning

AI-driven dynamic planning tools utilize inventory, orders, products, locations, and sales history data to refine demand forecast accuracy.

This leads to the ideal inventory level across the network, ensuring resources are allocated efficiently and effectively.

AI's role in transportation and logistics is transformative, leading to significant efficiencies and cost reductions and contributing to a more sustainable operational model.

As the logistics sector embraces AI, it moves towards a future marked by increased productivity, reduced environmental impact, and enhanced operational agility.

Navigating challenges and implementing AI in supply chains

Integrating Artificial Intelligence (AI) within supply chain operations holds transformative potential, promising unprecedented optimization and efficiency.

However, the journey towards full AI integration is not without its challenges.

Understanding these hurdles and developing strategic approaches is essential for businesses aiming to leverage AI effectively.

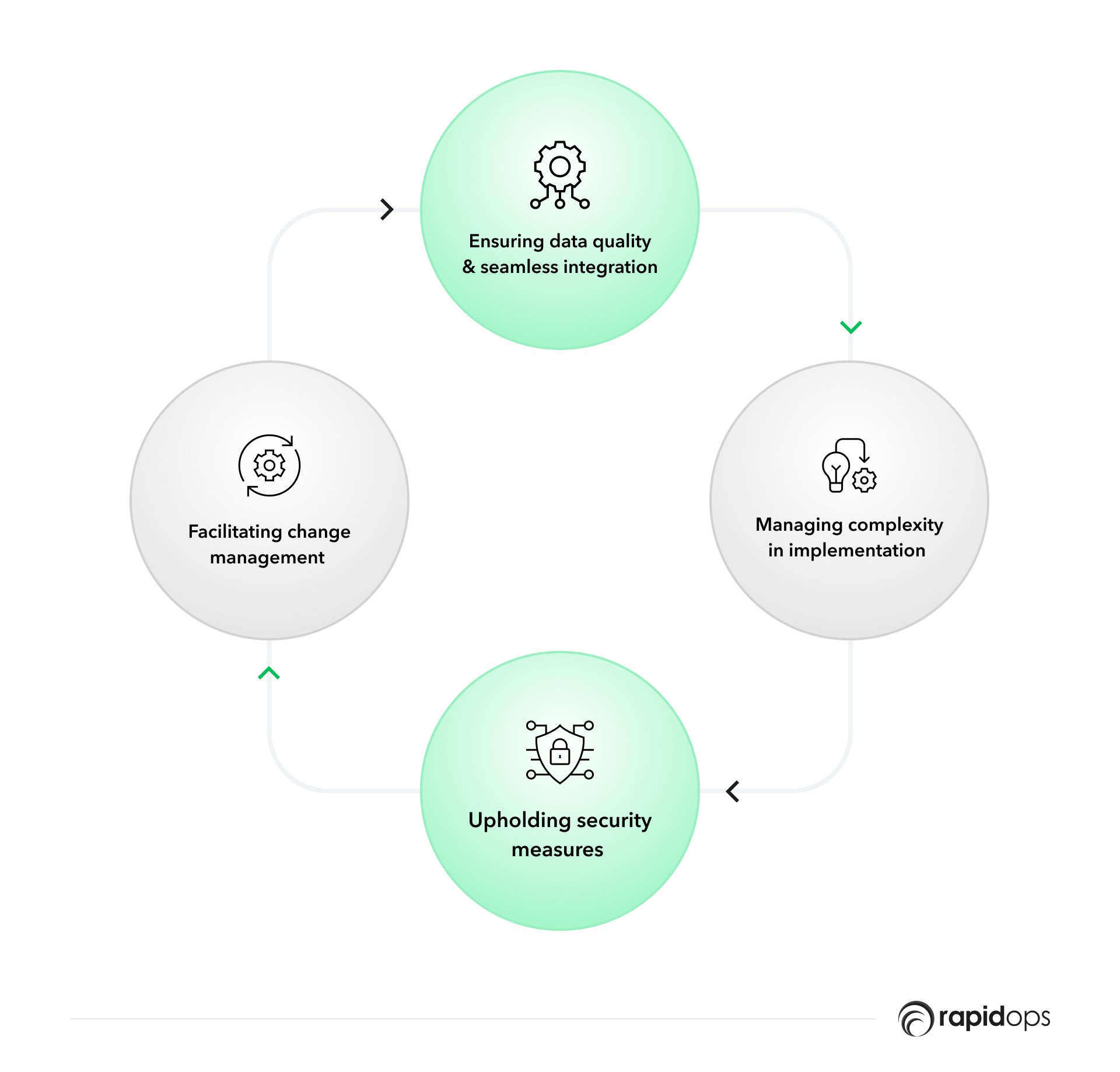

Unpacking common challenges in AI integration

1. Ensuring data quality and seamless integration

AI's effectiveness relies heavily on the availability of high-quality, integrated data across systems.

The challenge lies in harmonizing disparate data sources, ensuring data accuracy, and overcoming the inconsistencies that plague many organizations' databases.

2. Managing complexity in implementation

Weaving AI into the fabric of logistics and supply chain networks is complex and resource-intensive.

It demands a nuanced understanding of the technology alongside a deep insight into the specific business processes it aims to enhance.

3. Upholding security measures

As AI systems process and store vast amounts of data, securing this information against breaches and ensuring adherence to stringent data privacy laws become paramount.

The challenge extends to embedding robust security protocols that safeguard sensitive information without hindering system performance.

4. Facilitating change management

Introducing AI technologies necessitates substantial changes in operational workflows and employee roles.

Navigating this transition—training staff, addressing resistance, and redefining processes—requires careful change management strategies.

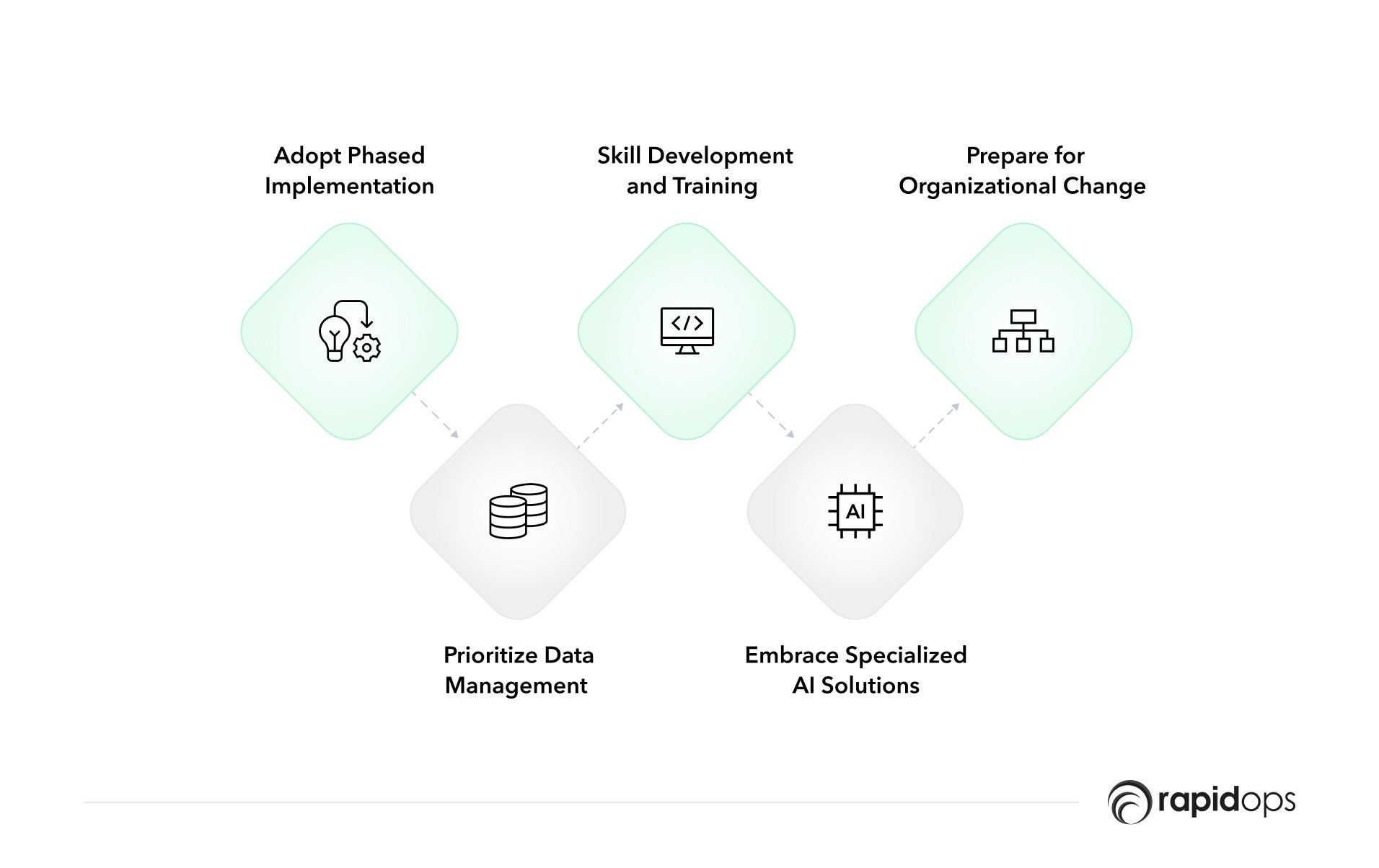

Strategic approaches for AI implementation

1. Adopt a phased implementation

Start with small-scale projects that can yield immediate benefits and serve as proof of concept.

This approach helps build momentum and secure buy-in for more extensive AI integration efforts across the supply chain.

2. Prioritize data management

Investing in data quality is foundational to AI success.

Initiatives might include data cleansing, establishing rigorous data collection protocols, and deploying advanced data management platforms to ensure the integrity and usability of data fed into AI systems.

3. Skill development and training

Building or enhancing your team's capability to deploy, manage, and leverage AI is crucial.

This could involve recruiting talent with specific AI expertise, upskilling current employees, or forming strategic partnerships with AI technology providers.

4. Embrace specialized AI solutions

Opt for AI solutions tailor-made for supply chain applications.

These specialized tools often come with shorter implementation timelines and are designed to tackle specific challenges within the supply chain domain, offering quicker returns on investment.

5. Prepare for organizational change

Anticipate the operational shifts that AI adoption brings.

Develop comprehensive change management plans that include staff training, workflow redesign, and continuous communication to ease the transition and foster a culture receptive to innovation.

Confront the challenges of AI in supply chain head-on with strategic planning. You unlock its full potential by overcoming data, talent, and implementation hurdles.

This transformation leads to a more efficient, agile, and competitive supply chain in today's marketplace.

Conclusion: Leveraging AI for strategic advantage in supply chain and logistics

Integrating Artificial Intelligence (AI) into supply chain and logistics has proven to be a game-changer, significantly enhancing operational efficiencies, reducing costs, and improving accuracy across the board.

This technological evolution is not just about automation; it's about enabling smarter, more strategic decision-making processes, optimizing resources, and fostering a more responsive and adaptable supply chain ecosystem.

For businesses looking to stay competitive and navigate the complexities of today’s market, embracing AI technology is no longer an option—it's a necessity. This is where Rapidops’ expertise becomes invaluable.

Rapidops as your AI development services partner

As you consider integrating AI into your supply chain and logistics operations, partner with an expert who can turn this complex technology into a strategic asset.

Rapidops delivers the expertise, tools, and insights needed to effectively use AI, streamlining your supply chain and logistics for improved efficiency and adaptability.

Take the definitive step towards transforming your supply chain and logistics operations by leveraging AI.

- Deep Understanding of AI: Rapidops has a profound knowledge of AI's practical applications and strategic implications in supply chain and logistics.

- Guidance Through AI Implementation: Equipped to navigate companies through the complexities of AI adoption.

- Full Leverage of AI's Potential: Ensures companies exploit AI fully to achieve their specific operational objectives.

With Rapidops, you gain a partner committed to delivering cutting-edge AI solutions tailored to your unique challenges and objectives.

Don’t let the opportunity to redefine your supply chain and logistics strategy with AI pass you by. Reach out to Rapidops today and unlock the full potential of your operations in this digital age.

How does AI improve demand forecasting in supply chains?

AI enhances demand forecasting by analyzing vast amounts of data from various sources, including historical sales, market trends, and consumer behavior. By leveraging machine learning algorithms, AI can accurately identify patterns and predict future demand. This allows businesses to optimize inventory levels, reduce waste, and improve customer satisfaction by ensuring the right products are available at the right time.

Can AI significantly reduce operational costs in logistics?

Yes, AI can significantly reduce operational costs in logistics. AI optimizes routing and delivery schedules and reduces fuel consumption and transportation costs. In warehouse management, AI-driven robots and automation systems streamline operations, reducing labor costs and improving efficiency. AI's predictive maintenance capabilities also prevent costly equipment failures, reducing operational expenses.

What role does AI play in enhancing customer experience in logistics?

AI is crucial in enhancing customer experience by providing personalized and efficient service. For instance, AI-powered chatbots offer instant customer support, while predictive analytics help anticipate customer needs and preferences. AI also ensures timely delivery of goods by optimizing routes and predicting possible delays, increasing customer satisfaction and loyalty.

How does AI contribute to sustainability in supply chains?

AI contributes to sustainability in supply chains by optimizing operations to reduce waste, energy consumption, and carbon emissions. For example, route optimization reduces fuel consumption and emissions from transportation. In inventory management, AI reduces waste by accurately forecasting demand, thereby preventing overproduction. AI also supports circular economy principles by helping companies identify opportunities for recycling and reusing materials.

What are the challenges in implementing AI in supply chain and logistics?

Implementing AI in supply chain and logistics comes with challenges, including data quality and integration, the complexity of AI systems, the need for skilled personnel, and security concerns. Ensuring high-quality, integrated data across systems is critical for AI's effectiveness. Additionally, businesses must invest in training to build AI expertise and adopt robust security measures to protect sensitive information.

Saptarshi Das

Content Editor

9+ years of expertise in content marketing, SEO, and SERP research. Creates informative, engaging content to achieve marketing goals. Empathetic approach and deep understanding of target audience needs. Expert in SEO optimization for maximum visibility. Your ideal content marketing strategist.

What’s Inside

- Use cases of AI in supply chain and logistics

- Enhancing forecasting and demand planning with AI

- Detailed case studies on AI in supply chain optimization

- Optimizing inventory management through AI

- AI in Logistics: Improving efficiency and reducing costs

- Navigating challenges and implementing AI in supply chains

- Conclusion: Leveraging AI for strategic advantage in supply chain and logistics

Let’s build the next big thing!

Share your ideas and vision with us to explore your digital opportunities

Similar Stories

- AI

- 4 Mins

- September 2022

- AI

- 9 Mins

- January 2023

Receive articles like this in your mailbox

Sign up to get weekly insights & inspiration in your inbox.