- Building Materials

- 17 min read

- July 2024

What Digital Transformation Means for the Building Materials Industry?

Key Takeaways

So, what digital transformation means for the building materials industry digitalization? Let's dive further.

Running a building materials business is a complex task. Rising costs, labor shortages, and fierce competition can make it seem impossible.

You manage supply chain issues, maintain customer satisfaction, and try to keep up with industry trends—all while ensuring your bottom line stays healthy.

Amidst all this, the term 'digital transformation' might sound like another daunting task on your to-do list.

Today, digital transformation in the building materials industry has advanced significantly. It is no longer limited to just automating basic processes or using digital tools for communication.

The industry is now leveraging advanced technologies like AI, IoT, and data analytics to revolutionize every aspect of the business.

With the right expertise and technologies, digital transformation can help you:

- Simplify operations: Automate routine tasks and integrate systems for seamless workflow.

- Boost sales: Utilize digital marketing and eCommerce to reach a wider audience and increase revenue.

- Gain efficiency: Optimize resources and processes to reduce costs and improve productivity.

- Manage costs better: Implement cost-effective solutions and improve financial management.

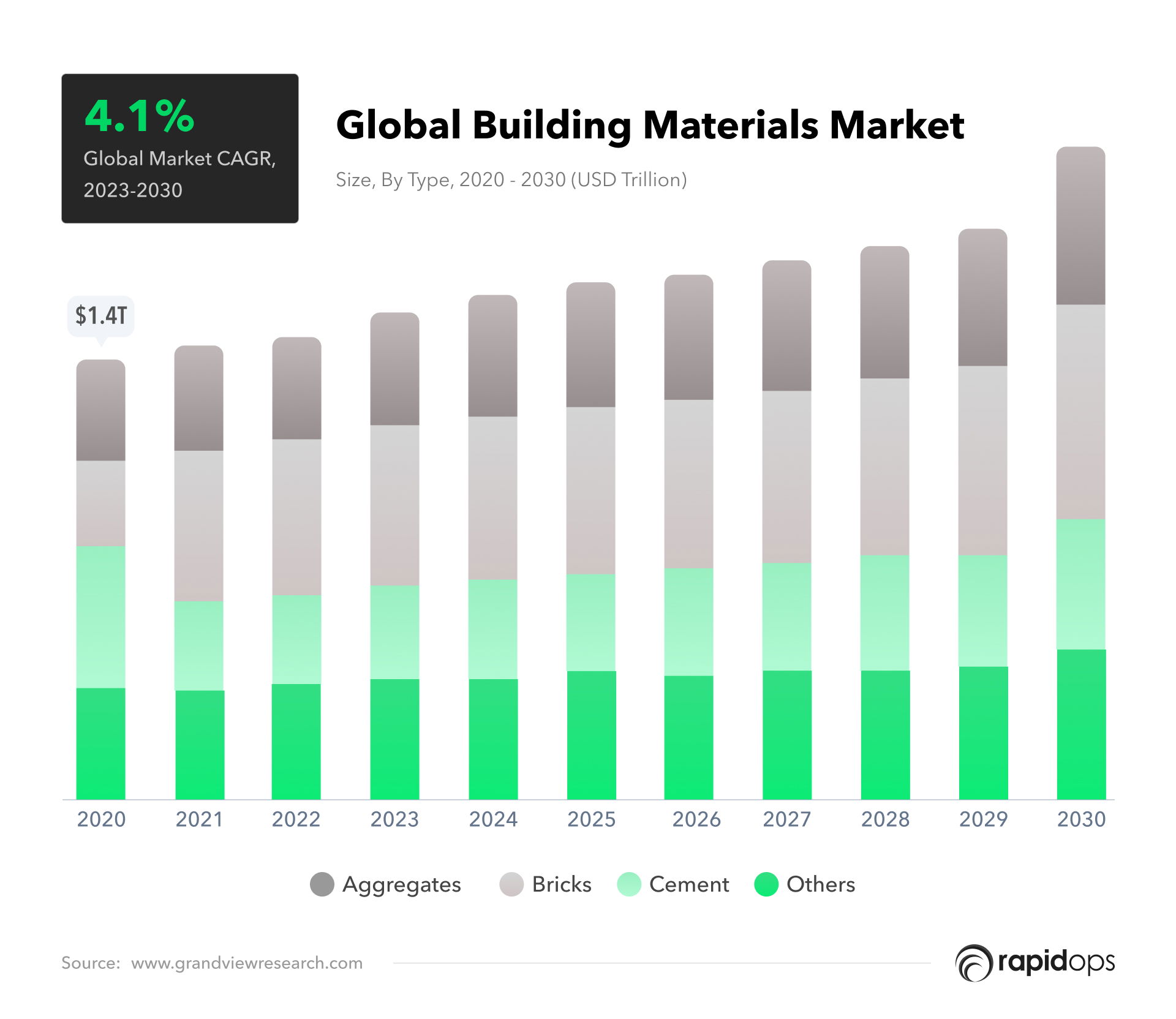

The global building materials market, with a valuation of USD 1.5 trillion in 2022, is anticipated to expand at a CAGR of 4.1% over the forecast period.

Substantial government investments in infrastructure projects drive this upward trajectory. Notably, these investments span critical sectors such as transportation systems, utilities, and public buildings.

As railways, mining, highways, non-residential structures, and tunnels continue to evolve, the demand for innovative infrastructure solutions remains paramount.

We must remind you that the building materials industry, which encompasses a broad spectrum of construction processes and materials, is at a pivotal stage of digital transformation.

In this blog, we're breaking down digital transformation into bite-sized, relatable pieces.

We understand your pain points and are here to offer real-world examples and practical steps to get started, providing the support and guidance you need to navigate this transformative journey.

Let's explore how you can turn challenges into opportunities and thrive in the modern marketplace.

Driving forces behind the urgency of implementing the building materials industry transformation

Running a building materials business comes with its own set of unique challenges. Let's start by addressing some of the most common pain points you might be facing daily:

1. Rising costs

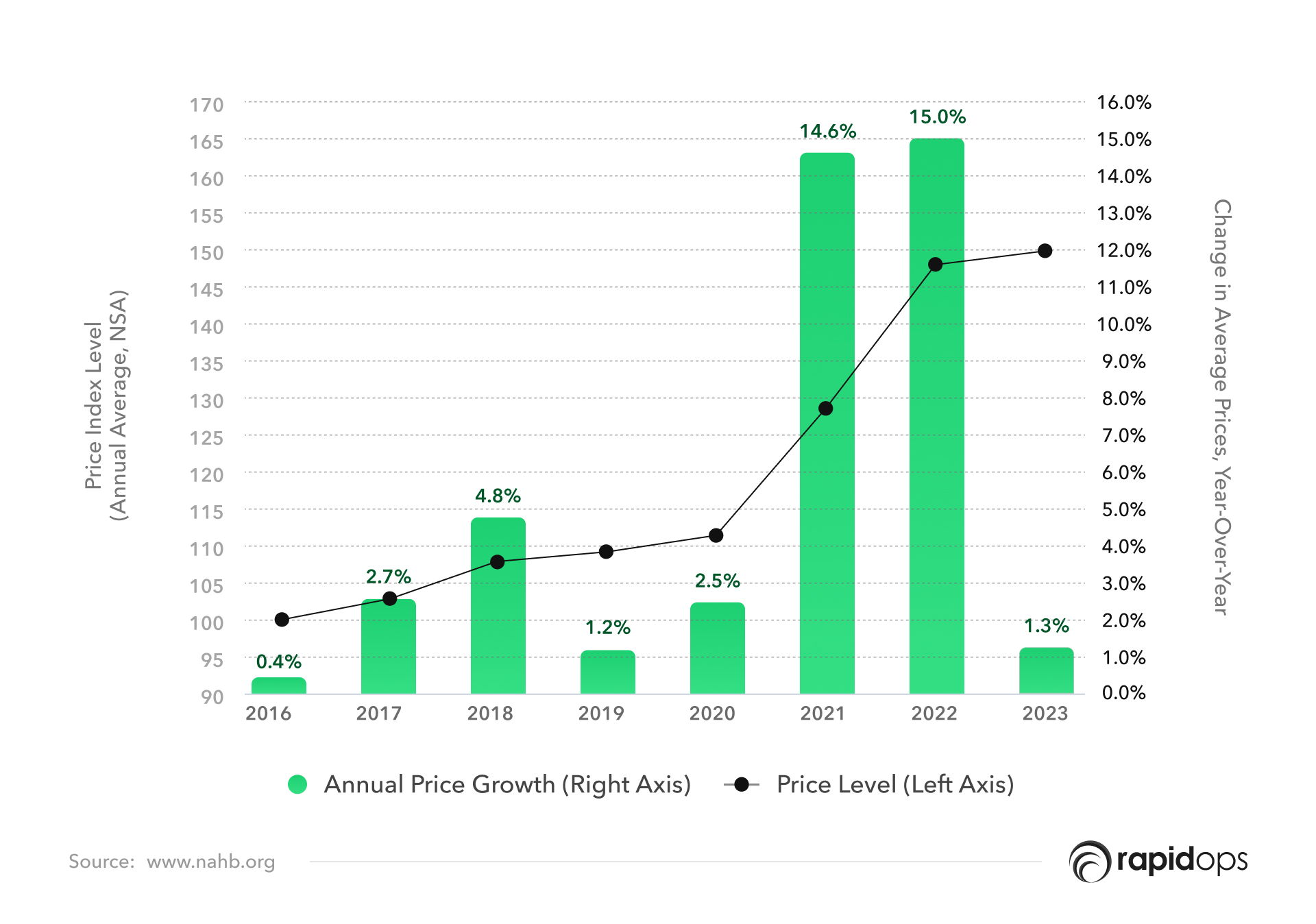

Building material prices fluctuate continually, making it hard to maintain steady profit margins. In 2023, while price increases for materials like lumber, drywall, and steel slowed compared to previous years, costs still rose nominally by 0.23% month-over-month.

Economists predict building material costs will increase between 2% and 4% in 2024.

Additionally, transportation costs, influenced by a potential "freight recession," present a mixed outlook, with some analysts predicting a 15% reduction and others a 5% increase. Overall, the cost of building materials and transportation remains a significant concern.

2. Rising customer expectations

Today's customers expect a seamless buying experience, whether they're shopping online or in-store. Meeting these expectations is critical to retaining loyal customers and attracting new ones.

The rise of eCommerce has further heightened these expectations, as customers demand easy access to product information, swift delivery times, and excellent customer service.

Fragmented customer experiences often result from siloed customer data, where outdated systems fail to provide a unified perspective. This leads to inconsistent service and missed personalization opportunities.

3. Operational inefficiencies

Manual processes and outdated systems can significantly slow down operations in a manufacturing plant, leading to errors and inefficiencies that eat into profits.

In the building materials industry, the reliance on antiquated methods for inventory management, order processing, and logistics hampers a company's ability to operate smoothly and efficiently.

Outdated and complicated legacy ERP and CPQ systems create bottlenecks and limit scalability, further contributing to these inefficiencies.

Manual tasks, such as tracking raw materials and managing production schedules, aggravate these issues, making it difficult to streamline operations and improve productivity in a highly competitive market.

4. Saturated Market

The building materials manufacturing industry faces unique challenges, especially in saturated or saturating markets, because it has covered most of the ground it can and has exhausted its manual resources.

Business owners must navigate these complexities by exploring new markets and avenues to remain competitive and drive transformation.

Key driving forces include:

Stagnant demand

In saturated markets, demand for traditional building materials often becomes stagnant. This stagnation can be attributed to several factors:

- Limited population growth: Developed countries experience slower population growth, reducing the need for new construction and, consequently, the demand for building materials.

- Increased efficiency in building design: Advances in building design have led to more efficient use of materials, requiring less per square foot of construction.

- Reuse of existing structures: There is a growing trend towards renovating and repurposing existing buildings rather than constructing new ones, further diminishing the demand for new materials.

Price competition

A saturated market often intensifies price competition. Manufacturers are finding it increasingly challenging to differentiate their products solely based on price, which can lead to a decline in profit margins.

Competing on the lowest prices can erode profitability, making it harder to sustain growth and invest in future initiatives.

Relying solely on low prices is not a sustainable strategy for manufacturers. It can limit their ability to invest in new products or technologies.

To maintain healthy profit margins and support long-term growth, manufacturers need to find other ways to differentiate their offerings beyond just price.

Limited innovation

Innovation becomes stifled in a saturated market. With established products and processes, there is often less incentive to invest in research and development for new materials or construction methods. This can result in:

- Stagnation in product development: Fewer breakthroughs in new building materials or innovative construction techniques.

- Reduced competitive edge: Companies that do not innovate may find it harder to stand out in the market, relying instead on outdated technologies and methods.

5. Labor shortages

The building materials manufacturing industry faces significant labor shortages that threaten productivity and operational efficiency.

With industrial demand high, as of June 2023, almost 600,000 stable manufacturing jobs were waiting to be filled in manufacturing businesses nationwide.

There are several critical factors contributing to this challenge:

- Aging workforce: A substantial portion of the current workforce is nearing retirement age, creating a gap that is not being filled quickly enough by younger workers.

- Skill gaps: The industry requires specific skills that are increasingly hard to find. Advanced manufacturing techniques and technologies demand a workforce that is proficient in new tools and methods, yet there is a shortage of training programs and apprenticeships to bridge this gap.

- Competitive job market: Building materials manufacturers are competing with other industries for the same pool of skilled labor. This competition drives up wages and makes it harder to attract and retain qualified employees.

According to the National Association of Manufacturers, the sector is facing a potential shortfall of 2.1 million skilled workers by 2030 if current trends continue. This shortage is driven by several factors, including:

- Technological advancements: Rapid advancements in manufacturing technologies require workers to update their skills continually. However, the pace of technological change often outstrips the availability of training programs.

- Economic uncertainty: Economic fluctuations can lead to workforce instability, making it challenging to maintain a consistent and skilled workforce.

A survey conducted by the Manufacturing Institute found that 77% of manufacturers report difficulties in attracting and retaining workers.

The same survey highlighted that 81% of manufacturers believe the skills gap will impact their ability to meet customer demand.

The construction industry, including building materials suppliers, is grappling with a significant labor shortfall.

The number of skilled workers leaving the job market far exceeds those entering it, leading to longer lead times and higher prices for building materials.

The labor market is expected to remain scarce, further complicating hiring and retention efforts.

Addressing these labor shortages requires a multifaceted approach:

- Investing in training programs: Developing in-house training programs or partnering with local educational institutions can help bridge the skills gap.

- Leveraging automation: Implementing automation and advanced manufacturing technologies coupled with co-bots can reduce dependency on manual labor and increase efficiency.

- Enhancing workforce attraction: Competitive wages, benefits, and a positive work environment can make the industry more attractive to potential employees.

6. Fierce competition

The building materials market is highly competitive, with numerous players ranging from large corporations to small local businesses.

Standing out in such a crowded market requires more than just quality products; it demands digitally transformed innovative approaches and superior customer service to attract and retain customers.

Missed sales opportunities often arise from an inability to adapt quickly to market changes or leverage data-driven insights effectively.

7. Supply chain disruptions

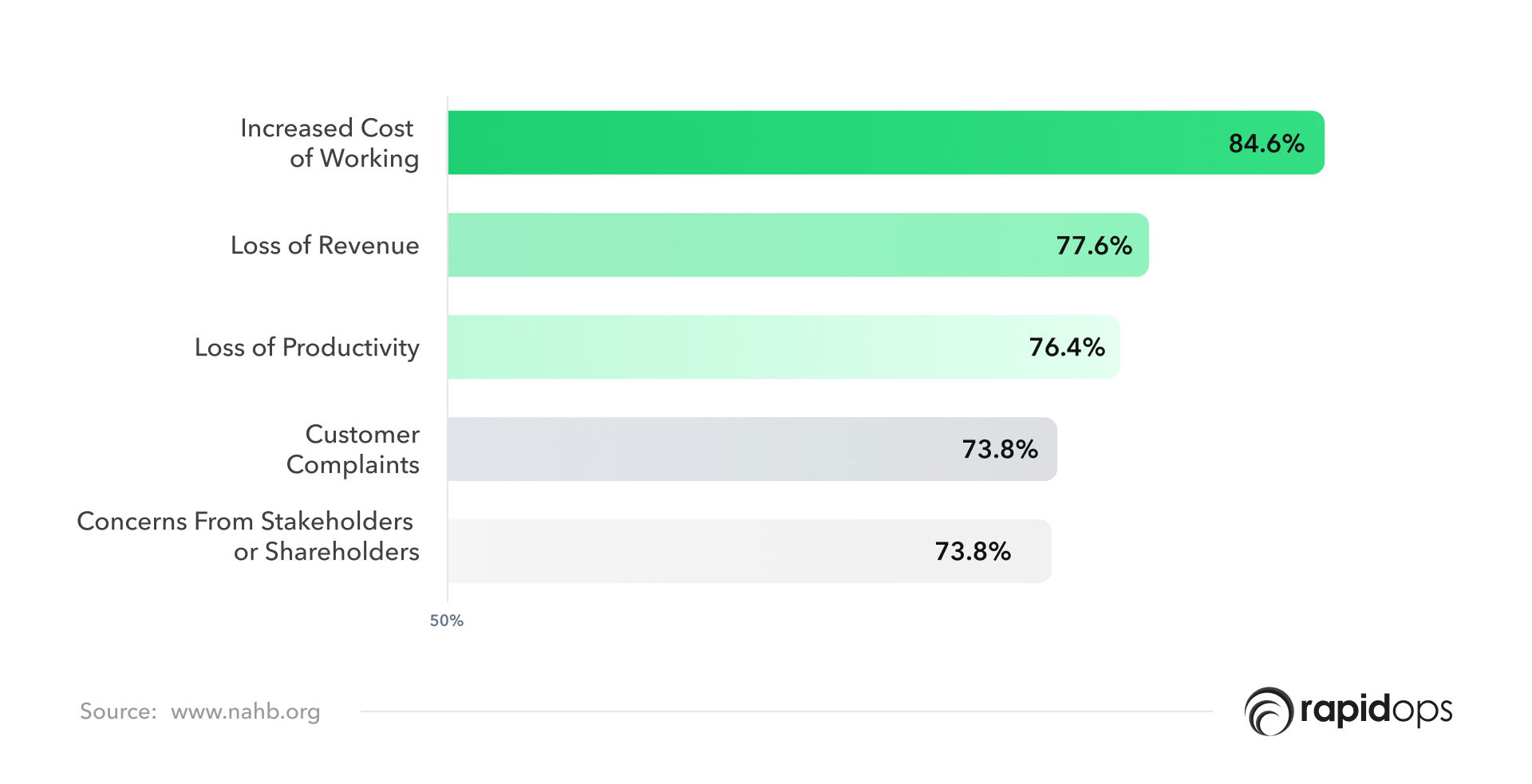

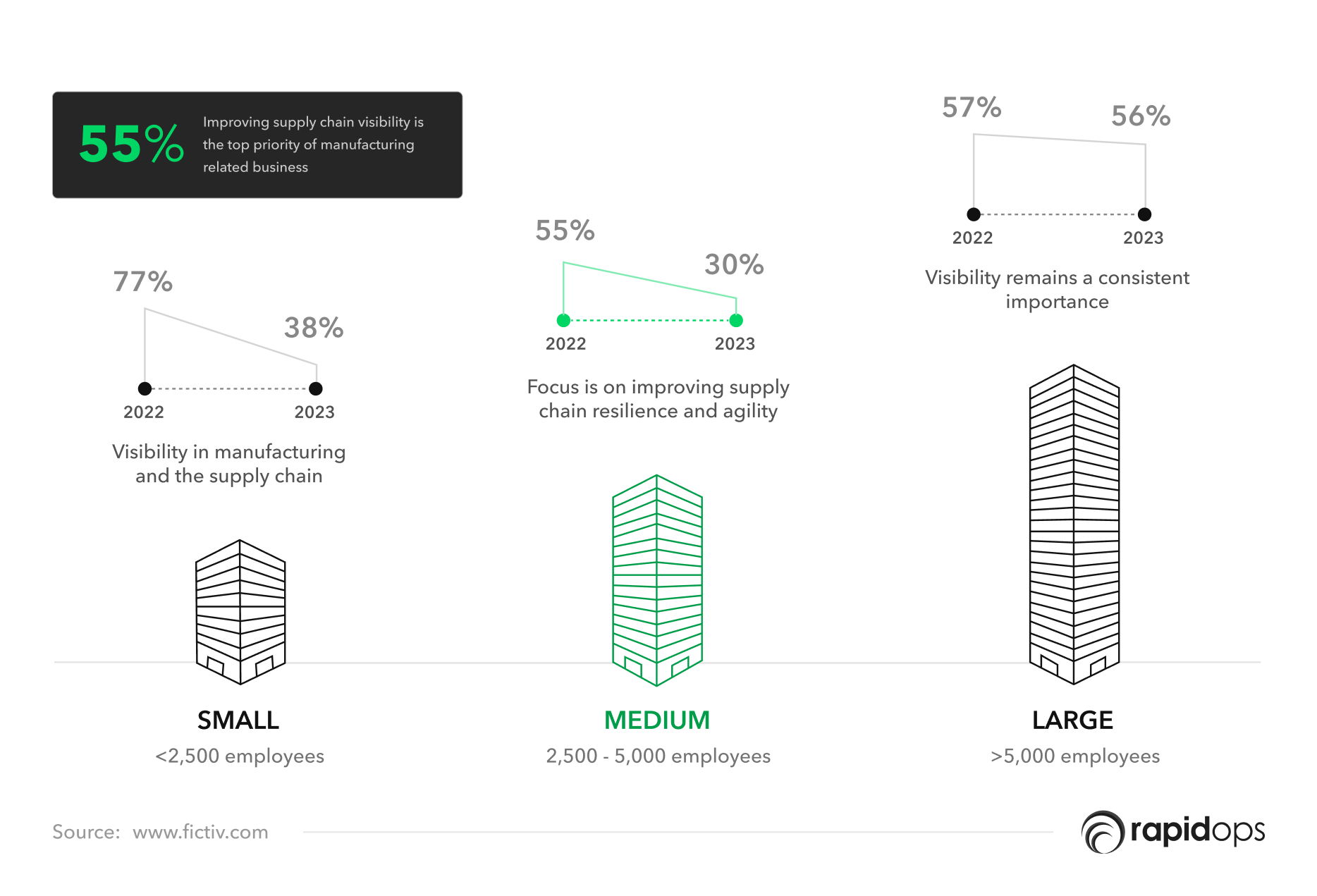

Supply chain disruptions have become a critical challenge for building materials manufacturers, significantly impacting production schedules, costs, and overall business stability.

The industry's reliance on a complex network of suppliers and the global nature of raw material sourcing makes it particularly vulnerable. Here are some insights from recent reports:

- Global trade instability: Trade policies and tariffs on key raw materials like steel and lumber have caused price volatility and supply inconsistencies. The National Association of Manufacturers (NAM) highlighted that tariffs have increased costs for 80% of manufacturers, directly impacting profit margins.

- Pandemic-induced disruptions: The COVID-19 pandemic caused delays and shortages of critical materials. According to the Institute for Supply Management (ISM), 75% of manufacturing firms reported supply chain disruptions due to the pandemic, with many expecting ongoing challenges.

- Transportation bottlenecks: Delays at ports and logistical bottlenecks have worsened supply chain issues. The American Trucking Associations' report highlights a critical challenge for the freight services industry: a significant driver shortage. At the close of 2018, the industry was short 60,800 drivers, unable to keep pace with national demand. This gap widened to a record 80,000 drivers in 2021 and is projected to exceed 160,000 by 2030 if current trends continue.

- Natural disasters and climate change: Weather-related disruptions like hurricanes, wildfires, and floods impact raw material availability and transportation routes. The Intergovernmental Panel on Climate Change (IPCC) warns that these events will likely become more common, necessitating robust supply chain strategies.

8. Changing building codes

Changes in building codes can have a wide impact on the building materials industry digitalization. For instance, updates to the International Residential Code in 2021 led to new building requirements in 2022.

These changes necessitate adjustments in processes and products to meet new regulations.

The ongoing updates to building codes and material standards are expected to continue, requiring manufacturers to stay agile and adaptive.

9. Fluctuating interest rates

Interest rates significantly impact building projects. In 2023, despite higher interest rates, U.S. home prices increased by 5.4%. For 2024, rates are expected to stabilize or even decrease slightly.

However, builders must still plan for potential fluctuations, as these can influence borrowing costs, project financing, and overall construction spending.

How digital transformation helps the building materials industry digitalization

The building materials industry is at a crossroads. Rising costs, supply chain disruptions, and labor shortages are squeezing margins and slowing growth.

But there's a solution: digital transformation. And as we explained at the start of the article, it isn't just about buzzwords.

By embracing digital tools, building material manufacturers can unlock a new era of efficiency, cost savings, and sustainability, giving them a better competitive edge.

The building materials industry faces a range of challenges in 2024, from managing rising costs and supply chain inefficiencies to addressing rising customer expectations and a saturated market.

Here's how digital transformation will be helping building materials manufacturers.

1. Move away from the chaos; take control by mastering efficiency and productivity

Automation and IoT

Integrating IoT sensors and automation technologies into manufacturing processes can significantly enhance efficiency.

Real-time data from IoT sensors can optimize production processes and facilitate predictive maintenance by monitoring machinery health, reducing downtime, and improving consistency and quality.

Automation helps manufacturers streamline repetitive tasks, increase production speed, and reduce errors.

AI-powered demand forecasting

AI can analyze historical sales data and market trends to predict future demand, enabling precise production planning and inventory management.

This reduces the risk of excess inventory and stockouts, ensuring that the right materials are available when needed.

2. Slashing costs with smart data

Data analytics

Data analytics helps identify cost-saving opportunities by analyzing customer behavior, market trends, and operational performance.

For instance, predictive analytics can forecast demand and manage inventory more effectively, reducing carrying costs and minimizing stockouts.

Cloud-based platforms

Implementing cloud-based platforms for centralized data management provides real-time access to critical information across the supply chain.

This enhances coordination between various stakeholders, improving decision-making and reducing operational inefficiencies.

3. Building a resilient supply chain for the digital age

Digital twins

Creating digital replicas of physical entities (digital twins) can simulate, predict, and optimize the building process.

This helps in managing disruptions in the global supply chain by providing a clear, real-time view of inventory levels and supply chain status.

Blockchain technology

Blockchain can create a transparent and secure record of transactions, improving trust and accountability in the supply chain.

This ensures that materials are sourced responsibly and that transactions are secure.

4. Attract, train, and retain top talent

Attracting talent with digital platforms

Digital platforms can help attract and retain talent by offering modern, technology-driven work environments.

These platforms can streamline HR processes, from recruitment to employee management, making it easier to manage the workforce.

Robotics and automation

Using robots for dangerous or repetitive tasks can improve safety and efficiency, reduce reliance on human labor, and address the labor shortage.

5. Digital tools for sustainable construction

Sustainable practices through digital tools

Digital technologies support sustainable construction practices by providing data and tools for reducing the embodied carbon of materials, implementing passive design principles, and using energy-efficient equipment.

Material passports

Material passports contain detailed information about the quality, origin, and location of materials, making it easier to reuse or recycle them, thereby supporting circular economy principles.

6. Market expansion for building a digital sales force

Modernized eCommerce platforms

Building a user-friendly online store allows businesses to reach a wider audience. Customers can place orders anytime, anywhere, leading to increased revenue and customer satisfaction.

eCommerce platforms enable companies to expand beyond local markets, attracting customers from different regions.

Digital tools for architects and builders

Providing comprehensive online product information, including detailed specifications and usage guidelines, helps architects and builders make informed purchasing decisions.

Offering Building Information Modeling (BIM) data for products allows for seamless integration into digital project models, enhancing collaboration and reducing errors.

7. Overcoming legacy ERP systems and fragmented data systems

Legacy ERP systems

Replacing outdated ERP systems with modern, integrated solutions can streamline operations and improve data accuracy.

Modern ERP systems facilitate better integration with other digital tools and platforms, reducing manual workflows and data entry errors.

Fragmented data systems

Consolidating fragmented data systems into a unified platform improves data accessibility and decision-making.

A centralized data system ensures that all stakeholders have access to accurate and up-to-date information.

8. Bridging integration gaps and enhancing customer experiences

Integration gaps

Closing integration gaps between different digital tools and systems ensures seamless data flow and operational efficiency. Integrated systems allow for better coordination and communication across departments.

Improved customer experience and engagement

Leveraging digital channels such as eCommerce platforms and mobile apps can enhance customer experience and engagement.

These digital touchpoints allow for easier product browsing, ordering, and delivery tracking, improving customer satisfaction and loyalty.

9. Developing a direct-to-customer strategy and enhancing CPQ capabilities

Direct-to-customer limitations

Building robust eCommerce platforms and direct sales channels can overcome direct-to-customer limitations, expand market reach, and improve customer relationships.

CPQ (Configure, price, quote)

Implementing CPQ software can streamline the sales process, allowing for accurate pricing, faster quotes, and personalized customer solutions. CPQ tools enhance sales efficiency and improve customer satisfaction.

By embracing digital transformation, building materials manufacturers can address their challenges and position themselves for future growth and success.

Digital tools and technologies offer opportunities to optimize processes, reduce costs, improve customer experiences, and stay competitive in a rapidly evolving market.

10. Automating regulatory compliance

Digital tools can simplify compliance with environmental regulations by automating the monitoring and reporting processes. This ensures that companies stay up-to-date with regulatory requirements and avoid penalties.

Business owners in the building materials manufacturing industry are always on their toes to ensure a good bottom line.

Having digital tools or software to manage the workload can help them focus their efforts on what matters most: sustaining their business and thriving to grow it!

Real-world example: Lumber giant Lowe's leverages digital transformation for growth

A prime example of digital transformation in the building materials industry digitalization is Lowe's Companies, Inc., a major distributor in the U.S.

Recognizing the need to adapt in an increasingly competitive market, the company embarked on a significant digital transformation journey, focusing on several key areas and yielding remarkable results.

1. Enhanced eCommerce platform

Lowe's invested heavily in their eCommerce platform, making it user-friendly and feature-rich. Key enhancements included:

- Product filtering: Customers could easily filter products based on various attributes, making it simpler to find exactly what they needed.

- Inventory availability checks: Real-time inventory updates allow customers to see product availability before making a purchase.

- Easy online ordering: Streamlined the online ordering process, reducing friction and making it more convenient for customers to complete their purchases.

2. Omnichannel strategy

The company implemented a robust omnichannel strategy, ensuring a seamless shopping experience across all customer touchpoints. Key elements included:

- Buy Online, Pick Up In-Store (BOPIS): Customers can browse and buy products online and pick them up at their convenience from a nearby store.

- Enhanced mobile app: The mobile app was upgraded to support on-the-go shopping, providing a consistent and convenient shopping experience whether customers were online or in-store.

3. Data-driven decision making

Lowe's leveraged data analytics to gain deeper insights into customer behavior and buying patterns. This data-driven approach allowed them to:

- Personalize product recommendations: Tailored product suggestions based on individual customer preferences and purchase history.

- Optimize inventory management: Ensured that the right products were in stock at the right time, reducing overstock and stockouts.

- Tailor marketing campaigns: Created more effective marketing campaigns by targeting specific customer segments with relevant offers and promotions.

The impact

The digital transformation efforts led to substantial benefits:

- Increased online sales: There was a significant growth in online sales, with many customers utilizing the BOPIS option for added convenience.

- Improved customer satisfaction: The seamless shopping experience, combined with the convenience of online purchasing and in-store pickup, resulted in higher customer satisfaction and loyalty.

- Enhanced operational efficiency: Data-driven insights allowed Lowe's to optimize inventory levels and streamline logistics, leading to significant cost savings.

Key takeaways

- This success story highlights the power of digital transformation for building materials businesses.

- By embracing new technologies and creating a seamless customer experience across all channels, the company stayed ahead of the curve and achieved impressive growth.

- Their journey underscores the importance of investing in eCommerce, adopting an omnichannel strategy, and leveraging data analytics to drive business success.

How does technology impact the building materials industry digitization?

Technological advancements in product development

New technologies are revolutionizing the building materials market at every stage, from research and development to product launches. The integration of advanced technologies is becoming increasingly prominent in the industry.

IoT and AI in manufacturing

The industry is leveraging the Internet of Things (IoT), including robots and sensors, to enhance and optimize manufacturing processes. Artificial intelligence (AI) algorithms are being integrated into sales and operations planning (S&OP), allowing companies to forecast production demand with greater accuracy.

BIM systems for better project management

Construction material producers are utilizing Building Information Management (BIM) systems to provide essential product information, such as carbon footprints. BIM systems facilitate architects in designing various construction project options, pricing, and estimating a building’s carbon footprint. This is crucial as the demand for green buildings continues to rise among investors and clients.

Optimizing logistics with On-Time-In-Full solutions

Logistics is another area undergoing rapid transformation. For contractors, timely and complete delivery of materials to construction sites is critical. Companies are adopting On-Time-In-Full solutions to streamline distribution center operations and ensure precise material deliveries, addressing the challenge of limited storage space at construction sites.

The digitization of sales

Shifting sales channels

while traditional sales channels like marketplaces, wholesalers, and specialized stores still dominate, there is a growing trend towards digital sales methods commonly seen in B2C sectors. Reports indicate that 49% of B2B spending is now online, with this figure expected to rise to 57% in the next five years.

Enhancing customer convenience

Customers in the construction sector expect to order products 24/7 and quickly access information about product availability. They also demand intuitive and user-friendly eCommerce platforms. Advanced search engines help users find products efficiently, while dedicated B2B eCommerce platforms offer tailored business terms and pricing.

Strengthening business relationships

Maintaining strong partnerships

Building strong relationships with traders and business partners is vital in the building materials industry. These relationships are often nurtured over years through regular meetings and industry events. eCommerce platforms can complement these efforts by automating routine tasks, allowing sales teams to focus on deepening customer relationships and exploring new sales opportunities.

Effective product management

Implementing PIM systems

Product Information Management (PIM) tools are essential for successful sales in the building materials industry. However, many companies lack the internal resources to fully utilize these systems. Only 13% of building materials companies have implemented PIM systems, highlighting a significant area for improvement. A centralized PIM system ensures consistency, automates updates, and reduces errors, facilitating efficient product management across multiple channels.

Streamlining catalog creation

A PIM system also accelerates the creation of product catalogs, a crucial marketing tool in the industry. Without a common product base, preparing these materials can take months. A centralized system simplifies this process, ensuring accurate and consistent product information.

How Rapidops helped its client integrate, automate, and digitize disjointed systems and processes

Enabling digital transformation in manufacturing

Client overview:

- Leading U.S. manufacturer and distributor of commercial hardware (doors, door frames, access control devices).

- 40+ facilities nationwide.

Challenges:

- Fragmented, paper-based processes due to distributed operations and acquisitions.

- Lack of integration and standardization among multiple isolated ERP systems.

Solutions implemented:

1. Digital strategy & design sprint:

- Conducted a two-week design sprint to create a clear roadmap and prioritize initiatives.

- Developed a prototype quickly to gain executive approval.

2. Legacy system augmentation:

- Engineered a platform to integrate and automate disjointed systems.

- Created a reusable API framework for agile app development.

3. Infrastructure & DevOps:

- Built on Microsoft Azure for scalability and reliability.

- Implemented Kubernetes for automated deployments and scaling.

4. UX/UI consistency:

- Developed a design system with reusable components for a unified user experience.

5. Supply chain modernization:

- Created a last-mile delivery platform to digitize and streamline the process.

- Features included order processing, real-time tracking, cost optimization, and digital proof of delivery.

6. Procurement automation:

- Digitized procurement approvals to reduce delays and improve transparency.

7. Sales efficiency:

- Automated discount approval process to speed up sales cycles.

8. Operational process automation:

- Automated accounts payable, integrating ERP and payment systems for efficiency.

- Integrated resource management systems to unlock business intelligence with PowerBI.

Impact:

- Realized cost savings, operational efficiencies, and improved customer experiences.

- Significant cultural shift towards a digital-first agile business model.

Concluding thought

So, I hope this article helped you understand what digital transformation means for the building materials industry.

The building materials industry digitalization is undergoing a profound transformation driven by digital technologies that are reshaping its operations.

It isn't just about keeping up with trends—it's about staying competitive and thriving in an increasingly forward-moving digital world.

Rapidops: Your partner in digital transformation

We understand that today's market presents unique challenges for the building materials industry digitalization. With over a decade of experience, we have worked with numerous manufacturers and assisted them in discovering the hook that was lacking in their systems.

By working closely with building materials companies, we have gained a deep understanding of their operations and needs. We develop innovative solutions that are designed to be flexible and responsive to the fast-changing landscape, helping your businesses grow, transform, and become more efficient.

Let's schedule a cost-free discovery call and discuss how we can help you leverage the latest technologies to overcome your industry's challenges and position your building materials manufacturing business for long-term success.

Frequently Asked Questions

Why is real-time inventory management crucial for building materials e-commerce?

How can advanced search and filtering options increase building materials sales?

What features should a building materials e-commerce platform have for B2B sales?

What features should a building materials e-commerce platform have for D2C sales?

What’s Inside

- Driving forces behind the urgency of implementing the building materials industry transformation

- How digital transformation helps the building materials industry digitalization

- Real-world example: Lumber giant Lowe's leverages digital transformation for growth

- How does technology impact the building materials industry digitization?

- The digitization of sales

- Strengthening business relationships

- Effective product management

- How Rapidops helped its client integrate, automate, and digitize disjointed systems and processes

- Concluding thought